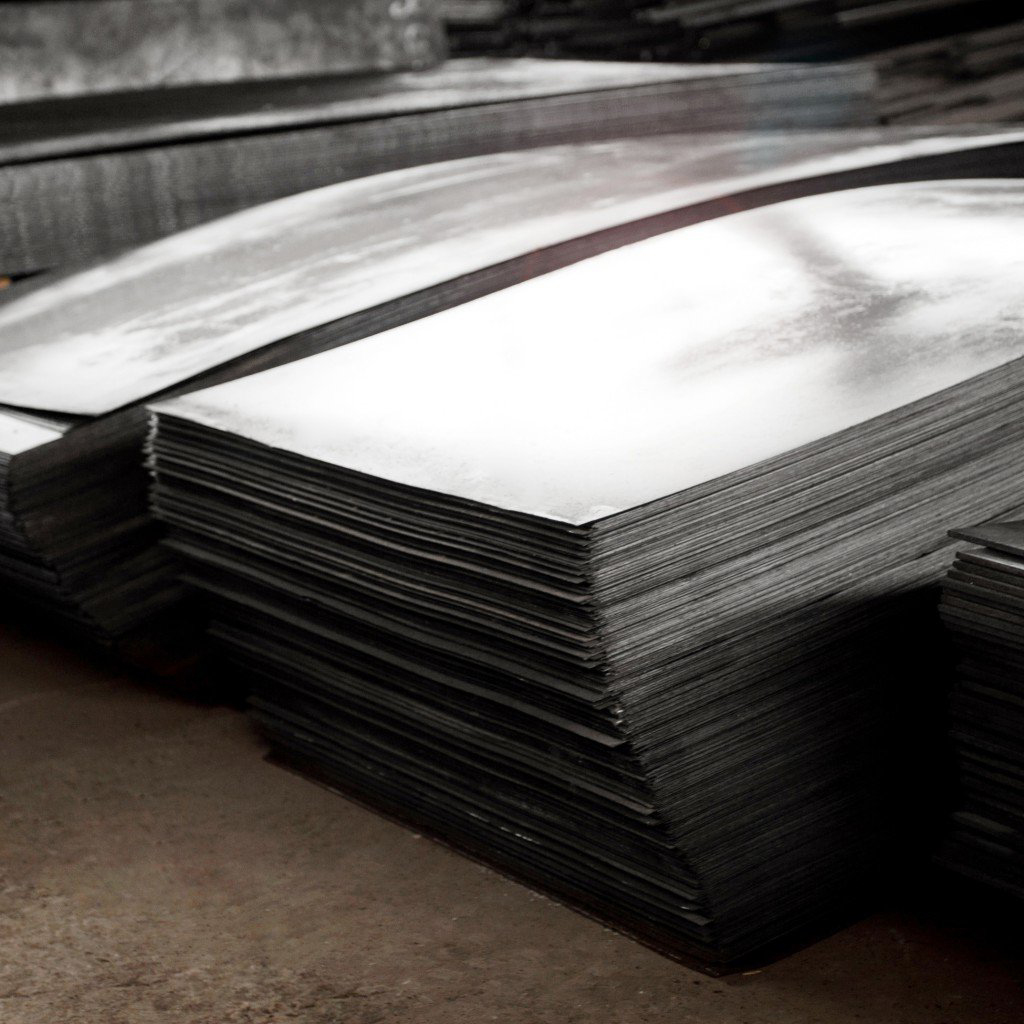

Birch FK plywood

Veneers are glued together using urea-formaldehyde resin. Owing to this adhesive component this type of plywood can be used indoors and in manufacturing furniture and other products because urea fumes are non-hazardous for people. It is mainly used for flooring (as a base layer underneath laminated or parquet flooring), interior decor, furniture production, containers and packaging. Not suitable for usage under high humidity conditions! Size of FK plywood 1525х1525mm, thickness from 3 to 30mm. Grades: 1\2, 2\2, 2\3, 2\4, 3\3, 3\4, 4\4. FK plywood can also be sanded and non-sanded.

Birch FSF plywood

Veneers are glued using phenol-formaldehyde glue, which is harmful to human health. Yet, this plywood has high strength and moisture resistance. Based on this characteristics, we can conclude that this plywood is used for outdoor work (exterior décor, rooftops), in aircraft and mechanical engineering, various construction works, etc. Suitable for high humidity environments! Size of FSF plywood 2440х1220mm, thickness from 4 to 40mm. Grades: 2\2, 2\3, 2\4, 3\3, 3\4, 4\4. FSF plywood can also be sanded and non-sanded.

Birch FOF (laminated) plywood

As a rule, FOF plywood is laminated FSF plywood, coated with thick paper that is saturated with phenol-formaldehyde resin. Such plywood is used to create formwork for cast-in-situ and low-rise construction. The paper covering plywood sheets serves as a barrier that prevents veneer from touching grout. It increases durability of the sheet. The turnover of laminated formwork plywood exceeds the turnover of ordinary FSF plywood several-fold. It can also be used to build children playgrounds. Size of FOD plywood: 2440х1220mm, 3000х1500mm, thickness from 6 to 40mm. Grades: 1\1, 1\2, 2\2, 3\3.

Birch FOF (mesh) plywood

Unlike ordinary laminated variety, mesh plywood possesses better adhesion for objects and soles of feet, so it is widely used in manufacturing trailers, wall cladding and flooring in trucks and coaches. It keeps slips to a minimum. Size of FOF mesh plywood: 2440х1220mm, 2500х1250mm, 3000х1500mm. Grades: 1\1, 1\2, 1\3, 3\3.

We just had a look at several main types of plywood. Now you know what kind plywood corresponds to each purpose. In the next article we will tell you about grades of plywood and their differences in more detail.